Clean Swabs stand out from regular cleaning swabs due to their superior performance, precision, and reliability, particularly in environments where contamination control and thorough cleaning are critical. Unlike standard cleaning swabs, which are often used for basic, general-purpose cleaning, Clean Swabs are specifically engineered to meet the stringent demands of specialized industries, such as healthcare, electronics, and pharmaceuticals. Their design, materials, and functionality set them apart, making them indispensable tools for professionals who require highly efficient and reliable cleaning solutions.

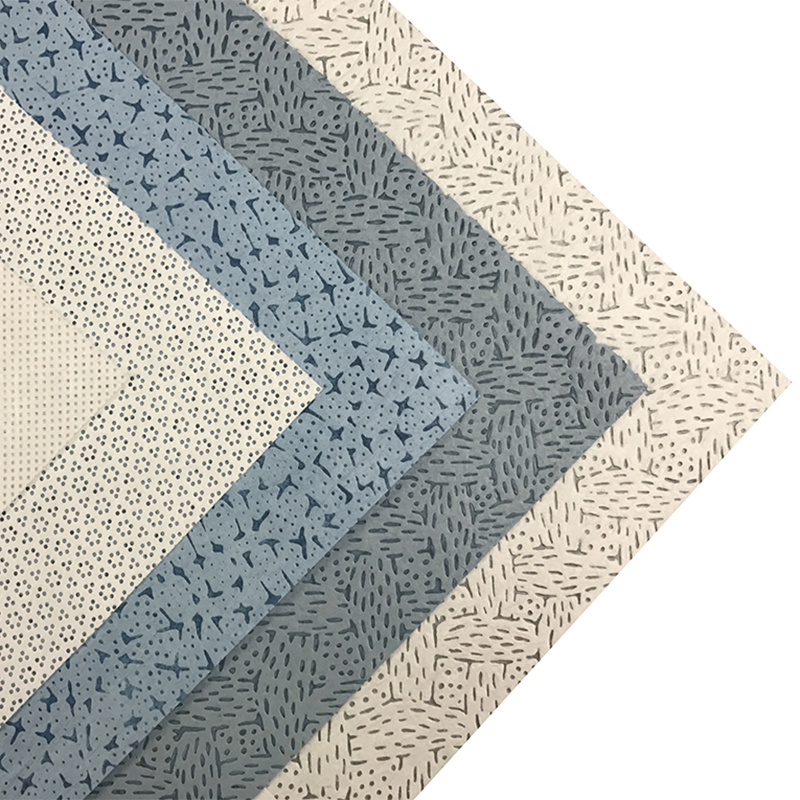

One of the key differences between Clean Swabs and regular cleaning swabs is the level of absorbency and the quality of the materials used. Clean Swabs are typically constructed with high-quality synthetic or natural fibers that ensure optimal absorbency and durability. This allows them to hold and distribute cleaning solutions more effectively, which is particularly important in delicate tasks like cleaning sensitive electronic components, medical devices, or laboratory equipment. Regular cleaning swabs may not offer the same level of absorbency or precision, often leading to incomplete cleaning or the need for multiple passes to achieve the desired result.

Another defining feature of Clean Swabs is their design, which is tailored to ensure maximum control and efficiency in cleaning. The tips of Clean Swabs are usually manufactured to be uniform and free of contaminants such as loose fibers or lint, which could otherwise interfere with the cleaning process. This is especially critical in environments where even the smallest particle could cause malfunctions or contamination. For instance, in the electronics industry, Clean Swabs are used to clean delicate components like circuit boards, where the presence of dust or fibers can lead to costly damage. Regular cleaning swabs, on the other hand, may shed fibers or leave traces of debris, which can compromise the quality of the cleaning.

In addition to their material and design, Clean Swabs are also produced under strict quality control standards. In industries like pharmaceuticals or biotechnology, where sterilization and contamination prevention are paramount, Clean Swabs are manufactured to be sterile and free from any biological contaminants. They undergo rigorous sterilization processes, such as gamma radiation or ethylene oxide treatment, to ensure that they are safe for use in sterile environments. Regular cleaning swabs may not adhere to such stringent standards, and using non-sterile swabs in sensitive areas could introduce contaminants, risking product integrity or patient safety.

The handle construction of Clean Swabs is another area where they outperform regular cleaning swabs. Often made from materials like polypropylene or other rigid plastics, the handles of Clean Swabs are designed for both strength and flexibility, allowing users to apply precise pressure during cleaning without the risk of breakage. The handles are also ergonomically designed to provide a comfortable grip, reducing fatigue during prolonged use. This level of design attention is important in professional settings where repetitive use is common, such as in cleanrooms or laboratories. Regular cleaning swabs, on the other hand, may feature less durable handles or a less user-friendly design, which can negatively impact the ease and effectiveness of cleaning tasks.

Reliability is another area where Clean Swabs excel. Because they are specifically designed for use in high-precision applications, they offer consistent performance over time. Whether they are being used to clean the surfaces of medical devices, semiconductor components, or optical instruments, Clean Swabs ensure that each cleaning task is completed to the highest standards. Their ability to maintain their shape, absorbency, and cleanliness throughout their use makes them a more reliable option than regular cleaning swabs, which may degrade or lose their effectiveness after a short period of use.

Furthermore, Clean Swabs are often designed with a specific task or industry in mind, which enhances their overall performance. For example, in the medical field, Clean Swabs might be designed with antimicrobial properties to prevent the growth of bacteria, ensuring that they are safe for use in clinical or surgical environments. In the electronics industry, swabs might have smaller tips for reaching into tiny crevices and components without causing damage. This specialized design ensures that Clean Swabs offer superior functionality in their designated applications, unlike regular cleaning swabs, which are often generic and less suited for high-precision tasks.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français