If you need any help, please feel free to contact us

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat are the core technical indicators of antistatic clothing?

The core technical indicators of antistatic clothing directly determine its protective performance. Suzhou Jujie Electron Co., Ltd. strictly adheres to industry standards to ensure that its products meet these standards:

Charge Decay Performance

antistatic clothing must quickly dissipate static electricity generated by the human body or the environment, with a charge decay time of 0.5 seconds or less. Suzhou Jujie Electronics uses conductive fiber blending technology to control the surface resistance of clothing to 10⁶-10⁹Ω, ensuring rapid static discharge and preventing the risks associated with static accumulation.

Surface Resistivity

Surface resistivity is a key indicator of clothing's electrical conductivity and must comply with standards such as GB 12014-2019, "antistatic Clothing." Suzhou Jujie Electronics' antistatic clothing maintains a stable surface resistivity of 10⁷-10⁹Ω, ensuring conductivity while preventing the effects of excessive conductivity on the human body or equipment.

Washability

antistatic performance must remain stable after multiple washes. Suzhou Jujie Electronics uses a special finishing process to ensure that the charge decay time of clothing remains ≤1 second after more than 50 washes, meeting the requirements of long-term use.

Cleanliness Indicators

antistatic clothing for cleanroom use requires controlled particle release. Suzhou Jujie Electronics' clothing is produced in ISO Class 5/6 cleanrooms, with a particle count (≥0.5μm) of ≤100 particles/cubic foot, meeting the requirements of high-purity environments such as semiconductors and pharmaceuticals.

How is the antistatic effectiveness of Suzhou Jujie Electronics' antistatic clothing verified in cleanroom environments?

Suzhou Jujie Electron Co., Ltd. utilizes comprehensive quality control and high-end testing equipment to ensure the reliable performance of antistatic clothing in cleanroom environments:

Production Environment Verification

The company operates an ISO Class 5/6 cleanroom, ensuring a dust-free production process throughout. From fabric cutting and sewing to packaging, everything is carried out in a clean environment to prevent contamination from external particles and ensure that the clothing's cleanliness meets cleanroom standards.

Equipment Testing Guarantee

The company is equipped with Japanese laser cutting machines and ultrasonic cutting machines to ensure burr-free edges and minimize particle generation. We also import high-end testing equipment such as infrared spectrometers and liquid particle counters from Germany, the United States, and South Korea. Each batch of antistatic clothing must undergo surface resistance testing, charge decay testing, and particle counting testing to ensure compliance with antistatic performance and cleanliness standards.

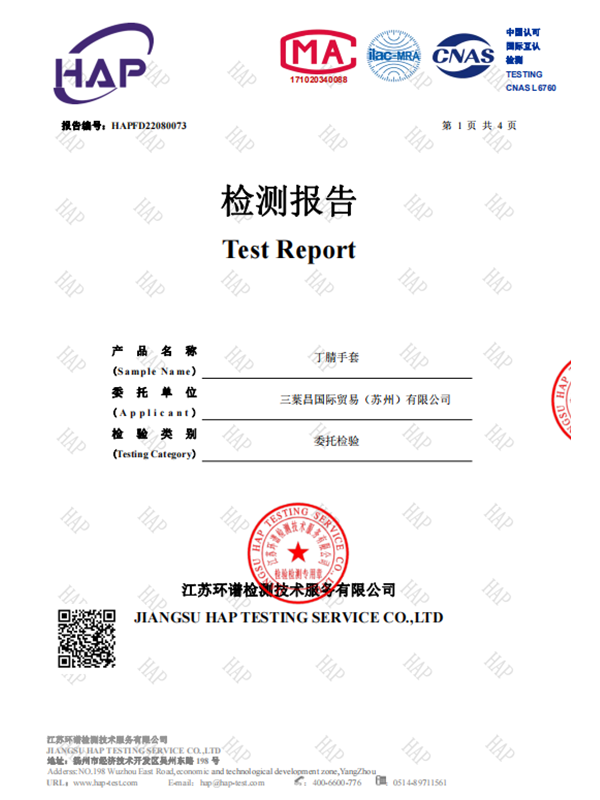

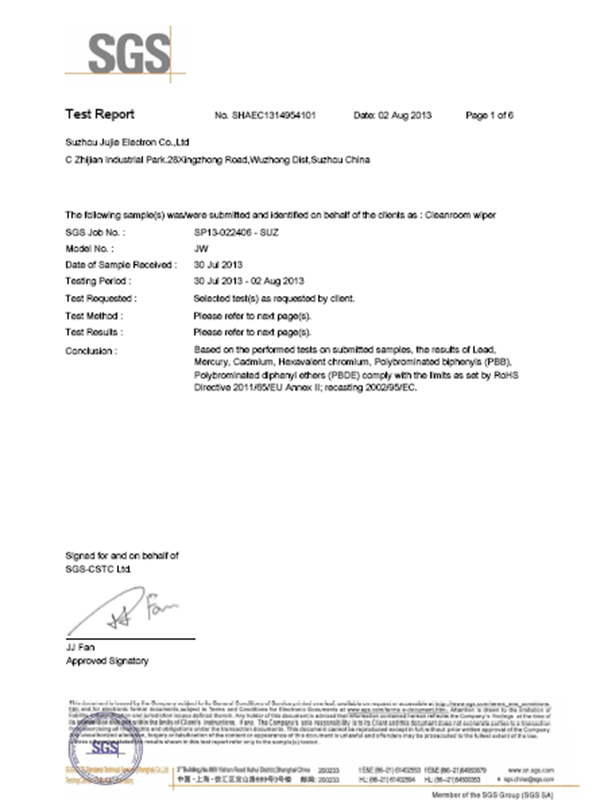

Third-Party Certification Endorsement

Products must pass authoritative certifications such as GB 12014-2019 "antistatic Clothing" and ISO 14644 Cleanroom Standards. Customized test reports are available for some products upon request.

Real-Scenario Testing

The company collaborates with cleanroom clients in the semiconductor and pharmaceutical industries, conducting real-world validation tests such as simulated cleanroom electrostatic discharge testing and particle settling testing to ensure the clothing effectively conducts static electricity and controls particles in real-world environments, meeting customer production requirements.

III. What industries are Suzhou Jujie Electronics' antistatic workwear suitable for? Suzhou Jujie Electron Co., Ltd.'s antistatic clothing covers a wide range of industries, offering diverse styles and customization capabilities to meet diverse needs:

Semiconductor/Electronics Manufacturing Industry

Semiconductor production places extremely high demands on static electricity and cleanliness. Suzhou Jujie Electronics' lapel antistatic clothing and hooded antistatic clothing (pictured) are made of antistatic fabric with stable surface resistance. Produced in ISO Class 5 cleanrooms, they effectively prevent static electricity from damaging chips and control particulate contamination, making them standard equipment in semiconductor factories.

Pharmaceutical/Bioengineering Industry

Pharmaceutical production must avoid particulate and microbial contamination. Suzhou Jujie Electronics' stand-up collar antistatic clothing and jackets offer excellent antistatic performance and low particle emission. Their breathable fabric makes them suitable for extended wear and meets GMP requirements.

New Energy/Photovoltaic Industry

In photovoltaic cell production, static electricity can easily cause cracks in the cells or degrade their performance. Suzhou Jujie Electronics' antistatic jackets and coveralls utilize conductive fiber technology to quickly dissipate static electricity from the human body, protecting battery cells from damage and improving production yields.

Precision Machinery/Aerospace Industry

Precision machinery assembly and aerospace component testing require antistatic and wear-resistant clothing. Suzhou Jujie Electronics' antistatic workwear utilizes wear-resistant fabric and antistatic properties, protecting precision components from static electricity and making it suitable for high-end manufacturing applications.