If you need any help, please feel free to contact us

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

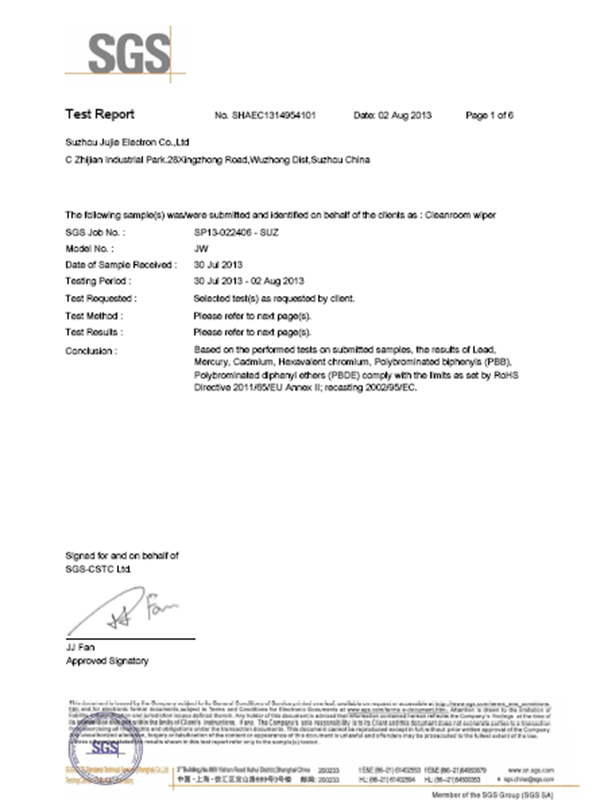

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat is the difference between antistatic mats and regular floor/table mats?

Regular floor/table mats are primarily designed for decoration, anti-slip properties, and water absorption, while antistatic mats are specialized for static protection. The two differ significantly:

Different Functional Properties

Regular mats: They only meet daily needs, such as water absorption, anti-slip properties, and decoration, but lack static control capabilities.

Antistatic mats: Through a conductive layer design, such as embedded metal wires or a conductive coating, they quickly conduct static electricity from the human body/device to the ground, preventing damage to electronic components and precision equipment caused by static discharge.

Different Technical Standards

Regular mats: There is no unified standard for static protection, and the material is solely focused on durability.

Antistatic mats: They must comply with standards such as ISO 14644 and ANSI/ESD S20.20. Suzhou Jujie products have also passed NEBB certification, ensuring both static discharge efficiency and cleanliness standards.

Differentiated Application Scenarios

Ordinary mats: Suitable for non-static-sensitive environments such as homes and ordinary offices.

Antistatic mats: Designed specifically for high-static-risk environments such as electronics factories, semiconductor workshops, laboratories, and medical cleanrooms. They are a core component of Suzhou Jujie's integrated "cleanroom + Antistatic" solution.

What types of Antistatic mats does Suzhou Jujie Electronics Co., Ltd. offer?

Leveraging a 33,000-square-meter modern factory and 48 fully automated production lines, Suzhou Jujie Electron Co., Ltd. offers a comprehensive Antistatic mat matrix, covering the needs of floors, desks, and special environments:

Antistatic and Anti-fatigue Floor Mats

Design: The surface features a non-slip texture and anti-fatigue structure, ensuring fatigue-free standing for extended periods.

Function: Combines static dissipation with ergonomic protection, making it suitable for high-frequency work environments such as electronics factory production lines and laboratory workstations.

Antistatic Desk Mats

Format: Available in rolls and sheets in a variety of sizes and thicknesses to accommodate various desktop sizes.

Features: The surface is smooth and easy to clean, and the edges are treated with an anti-curling finish to ensure complete desktop Antistatic protection.

Customized Antistatic Mats

Capabilities: Leveraging Japanese laser cutting machines and German infrared spectrometers, we support personalized customization of size, shape, and conductivity.

Applications: Meet the ESD protection needs of specialized environments such as semiconductor cleanrooms and medical equipment workshops.

What are the material and process characteristics of Suzhou Jujie's Antistatic mats?

Suzhou Jujie adheres to "technology-driven quality," and its Antistatic mats demonstrate industry leadership in material selection and production processes:

Material: Multi-layer composite structure, balancing performance and durability.

Conductive Layer: Utilizes highly conductive materials such as carbon fiber and metal wire to ensure rapid static discharge.

Base Layer: Utilizes wear-resistant PVC and anti-fatigue rubber for corrosion and aging resistance, with a service life exceeding 5 years.

Surface Layer: Customizable for different scenarios, such as textured anti-fatigue floor mats and smooth coatings for table mats, balancing functionality and user experience.

Process: Fully automated production lines and precision testing ensure consistency.

Production: 48 automated weaving, washing, and shaping production lines automate the entire "raw material-forming-cutting" process, increasing production capacity tenfold while eliminating manual errors.

Testing: Equipped with Japanese laser cutting machines and German liquid particle counters, each batch of products undergoes triple testing for electrostatic decay, wear resistance, and cleanliness to ensure consistent quality.

Technology: Cleanroom-grade production, suitable for high-end applications.

Workshop: 8,000 square meters of lint-free cleanroom built to ISO Class 5/6 standards, equivalent to Class 100 cleanliness in the semiconductor industry, eliminating particulate contamination during the production process.

Certification: Products are NEBB and ISO 9001 certified, meeting the stringent requirements of high-end industries such as medical and semiconductors.