If you need any help, please feel free to contact us

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat are the differences in the application scenarios of different types of antistatic tweezers?

Suzhou Jujie Electronics' antistatic tweezers are designed in multiple models for specific applications. The core differences lie in the tip shape, length, and material, covering the entire precision manufacturing process:

Tip Type: Precisely matches operating accuracy

Pointed Tip: The tip is as thin as a hair, suitable for ultra-precise operations such as semiconductor chip placement, fiber optic welding, and soldering microelectronic components, preventing damage to sensitive components due to excessive tip size.

Flat Tip: The tip is flat and wide, suitable for applications requiring uniform force, such as PCB component arrangement, battery electrode clamping, and optical lens assembly, to prevent components from slipping or surface scratches.

Angled Tip: The tip is curved at 15°-45°, designed for operations in confined spaces, such as internal equipment maintenance and micro-sensor debugging. It can reach deep into crevices for precise gripping, solving the pain point of straight-tipped tweezers.

Length Specifications: Suitable for Space Constraints

Short Version (100-120mm): Lightweight and flexible, suitable for laboratory benchtop operations and small equipment maintenance, allowing for precise single-handed control.

Medium-Long Version (150-180mm): Balances flexibility and reach, covering scenarios such as routine electronics assembly and medical device component assembly.

Extended Version (200mm and above): Targeted for long-distance operations such as internal inspection of large equipment and debugging of aerospace components, extending the reach while maintaining antistatic performance.

Customization for Special Scenarios: Non-magnetic antistatic tweezers suitable for MRI medical equipment and precision instruments, and high-temperature resistant versions suitable for high-temperature environments such as LED packaging and photovoltaic cell soldering. These are custom-developed by Suzhou Jujie Electron Co., Ltd. based on customer needs.

What are the materials and durability of antistatic tweezers?

Suzhou Jujie Electronics' antistatic tweezers are built around "high-performance materials + precision craftsmanship," ensuring both antistatic performance and long-term durability.

Material Selection: A balance of professional antistatic performance and durability.

Stainless steel (SUS304/316): A basic, mainstream material with corrosion and abrasion resistance, suitable for routine electronic assembly and laboratory operations.

Carbon fiber composite material: Lightweight (only one-third the weight of stainless steel), high strength, and excellent antistatic performance, making it suitable for weight-sensitive high-end applications such as aviation and medical.

Special alloy: Acid and alkali resistant, fatigue-resistant, and designed specifically for chemical and semiconductor wet processes to withstand corrosive environments.

Surface Treatment: Enhances wear resistance and slip resistance.

Laser Etching: Fine anti-slip grooves are added to the tweezer tip/handle to prevent slipping during operation and avoid scratching sensitive components.

Coating processes, such as nickel and chrome plating, enhance surface hardness, reaching over HRC50, extending service life and reducing maintenance costs.

Durability Verification: Full-Process Quality Control Guarantee

Production: Precision cutting using a Japanese laser cutting machine and ultrasonic welding for a reinforced structure prevent tip cracking.

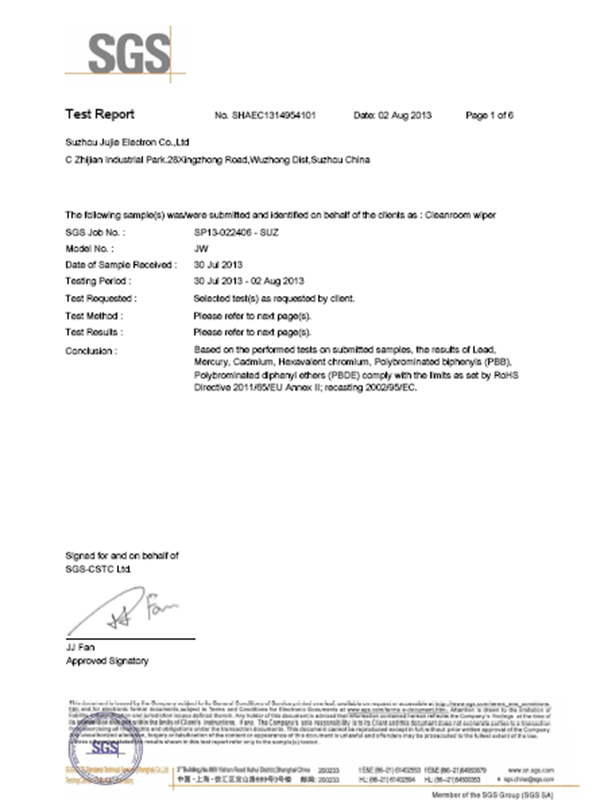

Testing: Material consistency is analyzed using a German infrared spectrometer, and cleanliness is tested using a US liquid particle counter to ensure consistent antistatic performance in each batch of tweezers.

Actual Testing: After 10,000 opening and closing cycles of fatigue testing and 500 hours of salt spray corrosion testing, the tweezer tips showed no noticeable deformation or coating loss, meeting the requirements of long-term industrial use.

What are the antistatic performance parameters of Suzhou Jujie Electronics' Antistatic Tweezers?

Suzhou Jujie Electronics' Antistatic Tweezers are designed with "precise static control + full-scenario adaptability" as their design goals. Their core parameters lead the industry:

Resistance Range: Covers sensitive scenarios.

Basic Model: Suitable for general electronics assembly, laboratory R&D, and other applications with moderate ESD sensitivity.

High-End Model: Designed specifically for ultra-high ESD protection applications such as semiconductor wafer handling and medical implant assembly, effectively preventing damage to precision components caused by electrostatic discharge (ESD). Static Decay Performance: Rapidly dissipates static electricity

The tweezers' static decay time is ≤ 0.1 seconds. Static electricity generated during operation is instantly discharged to ground, preventing static electricity accumulation from causing component breakdown and performance degradation.

Cleanliness Guarantee: Suitable for dust-free environments

Production: Assembled in an ISO Class 5 cleanroom, the tweezers' surface particle size is ≤ 0.1μm.

Packaging: Double-packed in an antistatic PE bag and vacuum-packed aluminum foil bag to prevent static electricity from attracting dust during transportation, ensuring cleanliness standards upon delivery.

Customizable Parameters: Meet special needs

For high-end applications such as aerospace and medical, we can customize special parameters such as low particle size and ultra-low resistance, with technical support provided by Suzhou Jujie Electronics' R&D team.