If you need any help, please feel free to contact us

Dust-free cloth is a special cleaning material, mainly used to clean and wipe sensitive equipment and surfaces to prevent the accumulation of dust and pollutants. They are usually made of microfibers and have high water absorption and low particle release properties. Dust-free cloths are widely used in industries such as electronics, medical, laboratory, and precision manufacturing to ensure the cleanliness of the environment and the high quality of products.

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhy are cleanroom wipes so "dust-free"?

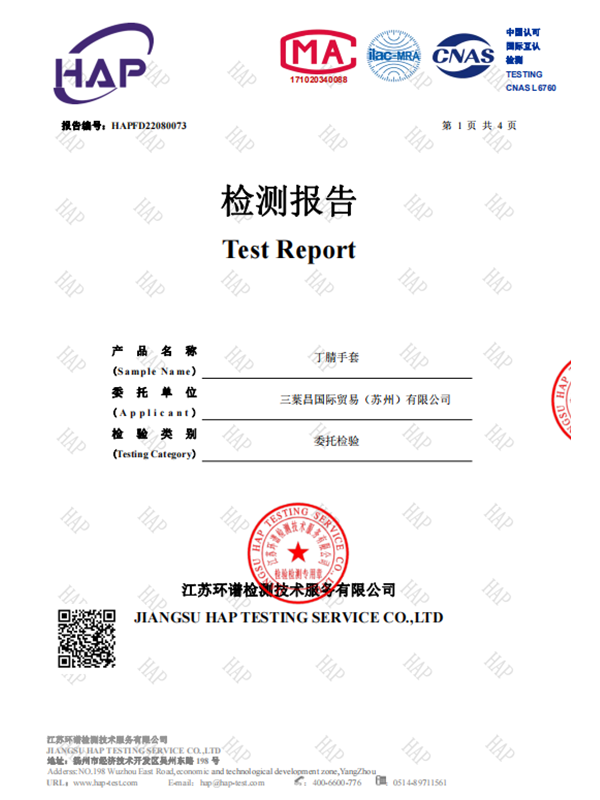

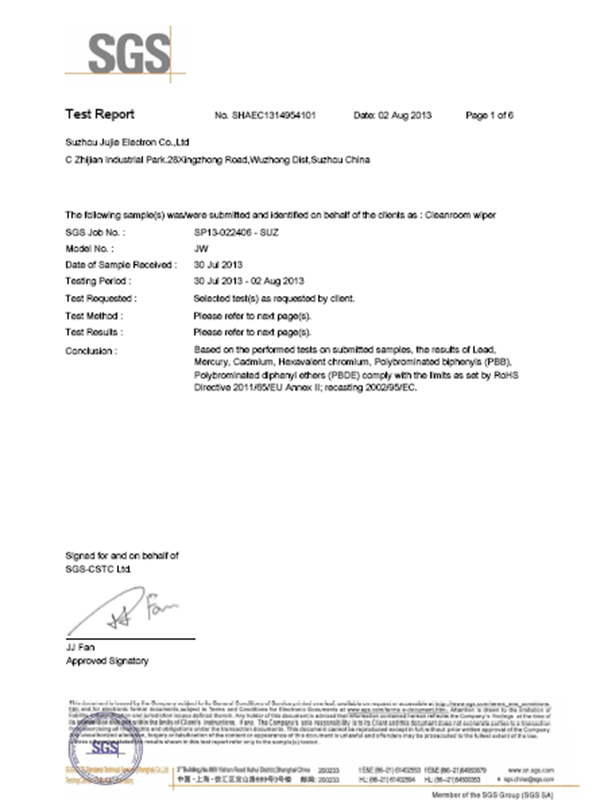

The dust-free nature of cleanroom wipes stems from the synergistic effect of their materials, craftsmanship, and design. Suzhou Jujie Electronics Co., Ltd.'s cleanroom wipers have further enhanced this core advantage through technological upgrades:

Microfiber Material: Physical Adsorption, No Residue

Cleanroom wipes are woven from microfibers. The microporous structure between the fibers physically absorbs dust and particles rather than pushing them away. For example, microfiber wipes like the JW-08522 and JW-09012 have a higher fiber density and capture over 99% of particles larger than 0.1μm, leaving virtually no residue on the surface after cleaning.

Low Particle Release Process: Strict Contamination Control in Production

Suzhou Jujie Electronics' cleanroom wipes are manufactured entirely in ISO Class 5/6 cleanrooms. From weaving and washing to shaping, every step ensures the elimination of external contaminants. For example, the JW-24011 double-layer polyester dust-free wiper utilizes a lint-free process, resulting in denser fibers on the surface, virtually eliminating particle shedding during wiping.

Anti-static function: Preventing static electricity from attracting dust

Some dust-free wipers, such as the JW-14061 anti-static wiper, have built-in conductive fibers to quickly dissipate static electricity. In the electronics industry, static electricity can easily attract airborne dust and damage sensitive components. This anti-static design eliminates the "dust-static" cycle at the source, ensuring a zero-residue cleaning process.

Specific Application Scenarios for Dust-Free Wipes in the Electronics Industry

The electronics industry, such as semiconductor and display production, requires extremely high cleanliness standards. Suzhou Jujie Electronics' Cleanroom Wipers cover the entire cleaning process, acting as "invisible guardians" of the production line:

Semiconductor Wafer Processing: Ultra-Clean Surface Cleaning

Semiconductor wafers require submicron-level surface cleanliness. The JW-18043 microfiber wiper's fine fibers precisely clean photoresist residue and metal particles from the wafer surface, preventing impurities from affecting chip yield.

LCD/OLED Display Production: Dual Protection Against Scratch and Static Electricity

The LCD roll-type wiper features a soft microfiber and anti-static coating, ensuring it cleans the fragile display layer without scratching it while also dissipating static electricity.

Electronic Equipment Maintenance: Precision Cleaning of Sensitive Components

The circuit boards and cooling fans of equipment like servers and routers are prone to dust accumulation. The JW-10012 microfiber wiper's wet/dry dual-use properties quickly remove dust without leaving any water marks, ensuring stable heat dissipation and signal transmission.

Cleanroom Environment Maintenance: Ensuring Air Cleanliness on Production Lines

The 1009LE cleanroom wiper is used to clean cleanroom walls, floors, and equipment casings. Its low dust release properties maintain an ISO Class 5 cleanroom environment for extended periods, preventing external contaminants from entering the production line.

How is the quality of Suzhou Jujie Electronics' cleanroom wipes guaranteed?

Suzhou Jujie Electronic Co., Ltd. builds quality barriers through comprehensive supply chain management and technological investment, ensuring that every cleanroom wiper meets the highest industry standards:

Production Environment: Cleanroom standards far exceed industry standards.

The company boasts an 8,000-square-meter lint-free cleanroom, NEBB-certified, which is over 10 times cleaner than ordinary cleanrooms. For example, the JW-24011 double-layer polyester cleanroom wiper is produced entirely in a constant temperature and humidity, dust-free environment to eliminate external contamination.

Production Equipment: Automation and High-End Guarantee

With 48 automated production lines (integrated weaving, washing, and shaping), equipped with imported Japanese laser cutting machines (cutting accuracy ±0.01mm) and German infrared spectrometers (to test fiber purity), production capacity has increased tenfold while achieving 99.9% product consistency.

Testing System: Comprehensive Quality Verification

Establishing a comprehensive testing process from raw materials to production to finished products:

Raw Materials: Infrared Spectrometer to Test Fiber Purity;

Production: Liquid Particle Counter to Monitor Wash Water Cleanliness;

Finished Products: Particle Release Testing, Water Absorption Testing, and Antistatic Performance Testing.

Technological Iteration: Continuously Optimizing Product Performance

In 2018, Suzhou Jujie Ultra-Clean Technology Co., Ltd., Shuyang Branch, was established as a wholly-owned subsidiary to expand production capacity and upgrade technology. For example, our sub-microfiber cleanroom wipes utilize "fiber refinement + surface modification" technology to increase capture rates of 0.3μm particles by 15%, making them more suitable for high-end applications such as medical and semiconductor applications.