If you need any help, please feel free to contact us

Nonwoven wiping paper towels is a disposable cleaning product made of nonwoven materials, which has high water absorption and a good cleaning effect. They are commonly used in industrial, medical, laboratory, and domestic Settings to wipe surfaces, clean equipment or remove stains. Nonwoven wipes are ideal for maintaining hygiene and cleaning due to their durability, ease of use, and single-use characteristics.

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

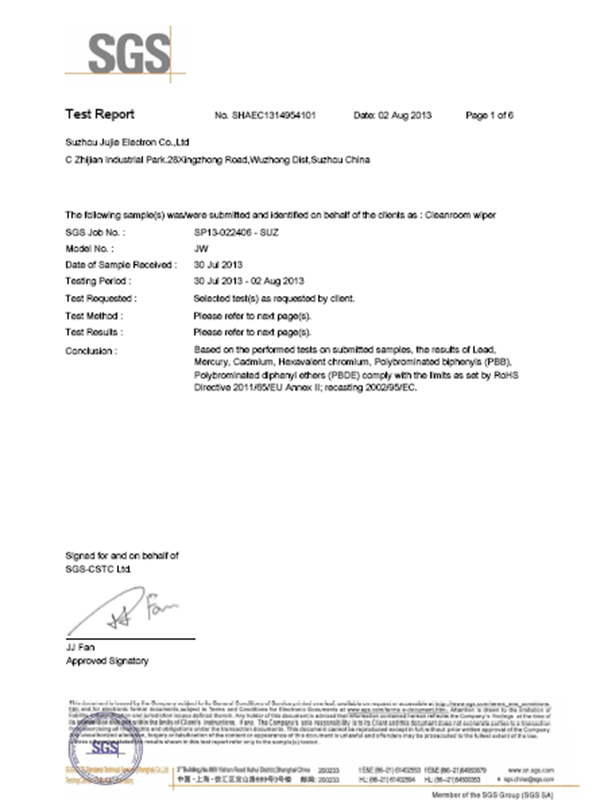

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat are the differences between household and industrial nonwoven wipes?

The demand for nonwoven wipes in household and industrial settings differs significantly. Suzhou Jujie Electron Co., Ltd. customizes its products for different scenarios, with key differences reflected in performance, specifications, and certifications:

Different Performance Emphasis

Household: Focuses more on skin-friendliness and gentleness. For example, lens cleaning wipes need to avoid scratching screens, while tub wipes are designed for daily surface cleaning.

Industrial: Emphasizes durability, anti-static properties, and low dust levels. For example, SMT automatic stencil wipe rolls require anti-static properties to protect electronic components, while PP meltblown wipes require high strength and abrasion resistance for cleaning mechanical parts.

Specifications and Forms

Household: Products are often small and portable, such as individually packaged wipes and boxed tissues, meeting daily cleaning needs.

Industrial: Products are primarily large rolls and bulk packaging, such as heavy-duty wipe rolls and SMT wipe rolls, suitable for automated production line cleaning and reducing roll change frequency.

Differences in Certifications and Standards

For home use: Products must meet civilian safety standards, such as being free of fluorescent agents and non-irritating.

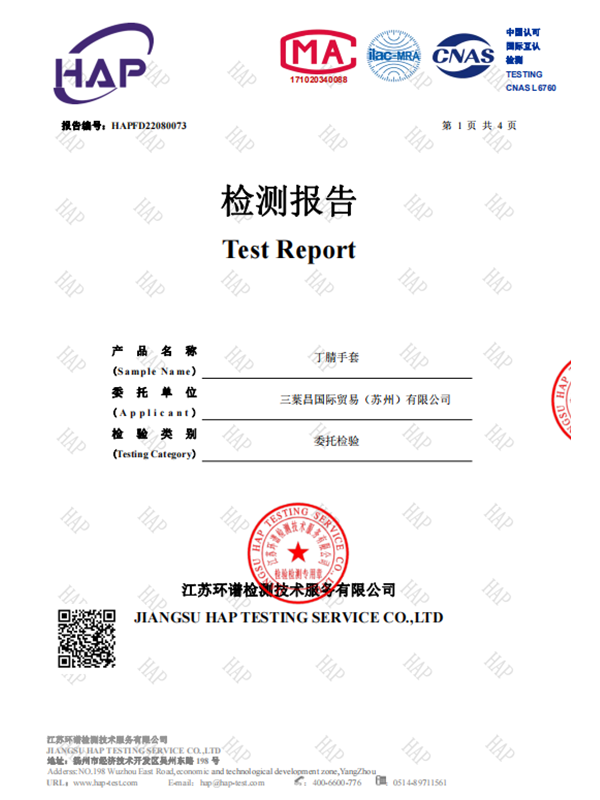

For industrial use: Products must pass stringent industry certifications, such as Suzhou Jujie's ISO Class 5/6 cleanroom production, ensuring dust-free and anti-static properties, meeting the high-purity requirements of applications such as semiconductors and pharmaceuticals.

How are nonwoven wipes used in industrial, medical, and laboratory settings?

Suzhou Jujie Electron Co., Ltd.'s nonwoven wipes, with their strong absorbency, low dust content, and durability, have become essential cleaning products for a variety of cleaning scenarios. Specific applications are as follows:

Industrial: Precision equipment and production line cleaning

Electronics manufacturing: SMT automatic stencil wipes are used to clean printed circuit board stencils to prevent solder paste residue. PP meltblown wipes are used to wipe mechanical parts, offering wear resistance and debris-free operation.

Automotive manufacturing: Heavy-duty wipes are used to clean engines and car bodies, removing oil stains while protecting metal surfaces from scratches. Medical Use: Disinfection and Surface Cleaning

Operating Room: Dust-free nonwoven wipes for wiping operating tables and instruments to prevent cross-infection;

Daily Care: Bottled wet wipes for cleaning patient ward tables and beds, containing disinfectant to quickly kill germs.

Laboratory Use: Cleaning high-precision samples and equipment

Biological Laboratory: Lens Cleaning Wipes for wiping microscope and centrifuge lenses to prevent fingerprints and dust from interfering with observation;

Chemical Laboratory: Polypropylene Lens Cleaning Wipes are chemical-resistant and can clean test tubes, beakers, and other glassware without leaving residue.

Why are Suzhou Jujie's nonwoven wipes so absorbent and effective?

Suzhou Jujie Electron Co., Ltd.'s nonwoven wipes boast superior absorbency and cleaning performance, stemming from three key pillars: material selection, production process, and testing system.

Material: Selected nonwoven fabric substrates.

Using high-performance fibers such as polypropylene (PP) and polyester (PET), these nonwovens are made through thermal or chemical bonding. The resulting fibers have small, uniform pores, allowing them to quickly absorb and retain moisture while also reducing lint and lint shedding.

Production: Strictly clean environments and advanced equipment.

Cleanroom standards: ISO Class 5/6 cleanrooms ensure a dust-free and sterile production process, preventing impurities from affecting product performance.

Automated production lines: 48 fully automated weaving, washing, and shaping lines, equipped with Japanese laser and ultrasonic cutting machines, ensure uniform fabric thickness and clean edges, enhancing friction and durability during cleaning.

Testing: High-end Equipment Ensures Quality

Equipped with infrared spectrometers and liquid particle counters imported from Germany and the United States, each batch of product is rigorously tested for water absorption, cleaning efficiency, and dust-free properties to ensure that every wipe performs consistently.