If you need any help, please feel free to contact us

A shoe cover is a protective shoe cover, usually made of plastic or fabric, designed to cover the shoe to keep it clean. They are used in situations where it is necessary to keep the floor clean or avoid shoes polluting a specific environment, such as hospitals, laboratories, clean rooms, etc. The shoe cover is easy to put on and take off, helping to maintain environmental hygiene and prevent cross-contamination.

Best Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreThe best materials for Cleanroom Wiper for electronic screens and optical components: 1. Microfiber Polyester: Made of 100% polyester microfibers with...

View More1. Warm water + neutral detergent: Wet a soft cloth or sponge with warm water (not hot), add a few drops of ordinary detergent, and gently wipe the St...

View More1. Definition: A Sticky Roller is a roller cleaning tool with an adhesive surface and a long handle. Simply roll it over the surface to be cleaned to ...

View MoreWhat's the difference between antistatic shoe covers and disposable shoe covers?

Although both antistatic shoe covers and disposable shoe covers are shoe covers, they differ significantly in their core functions, applicable scenarios, materials, and usage logic. Suzhou Jujie Electron Co., Ltd., a professional cleanroom shoe cover manufacturer, differentiates these two product categories to precisely meet the needs of different industries:

1. Core Function Difference: antistatic vs. Basic Protection

antistatic shoe covers: Their core function is to eliminate static electricity. Through their special conductive material design, they conduct static electricity generated by the human body or shoes to the ground, preventing damage to precision electronic components and semiconductor production lines. For example, in cleanroom environments such as electronic chip manufacturing and lithium battery production, where static electricity can potentially render products useless, antistatic shoe covers are essential protective equipment.

Disposable shoe covers: Their core function is basic isolation. They primarily prevent dust, bacteria, and contaminants carried by shoes from entering clean or sterile environments, such as hospital operating rooms, laboratories, and food processing workshops. They are often made of ordinary plastic or non-woven fabric, lack a conductive design, and focus on "physical isolation" rather than "static control."

2. Differences in Application Scenarios: High-Precision vs. General Use

antistatic Shoe Covers: Focus on high-precision cleanrooms. They are suitable for electrostatic-sensitive industries such as electronics, semiconductors, optoelectronics, and pharmaceuticals, requiring environments that meet ISO Class 5/6 standards. Suzhou Jujie's antistatic shoe covers, for example, are designed specifically for these applications and meet the stringent electrostatic control standards of cleanrooms.

Disposable Shoe Covers: Cover a wide range of general-purpose applications. They can be used in hospitals, laboratories, food factories, and homes, wherever it is necessary to prevent shoe contamination. Suzhou Jujie's disposable shoe covers focus on ease of donning and doffing and cost-effectiveness, making them suitable for large-scale consumption needs.

3. Differences in Material and Durability: Specialized Conductive Materials vs. General-Purpose Isolation Materials

antistatic Shoe Covers: The material must be both conductive and durable. Suzhou Jujie's products utilize a composite of special conductive fibers and wear-resistant fabrics to ensure static conduction while extending their lifespan. They can be reused multiple times and are suitable for long-term cleanroom operations.

Disposable Shoe Covers: Materials are primarily low-cost and disposable. Most are made of polyethylene plastic or non-woven fabric. They are lightweight, easy to put on and take off, but lack durability and are suitable for short-term or temporary protection.

How does Suzhou Jujie ensure product quality?

A comprehensive control chain from hardware, standards, and testing.

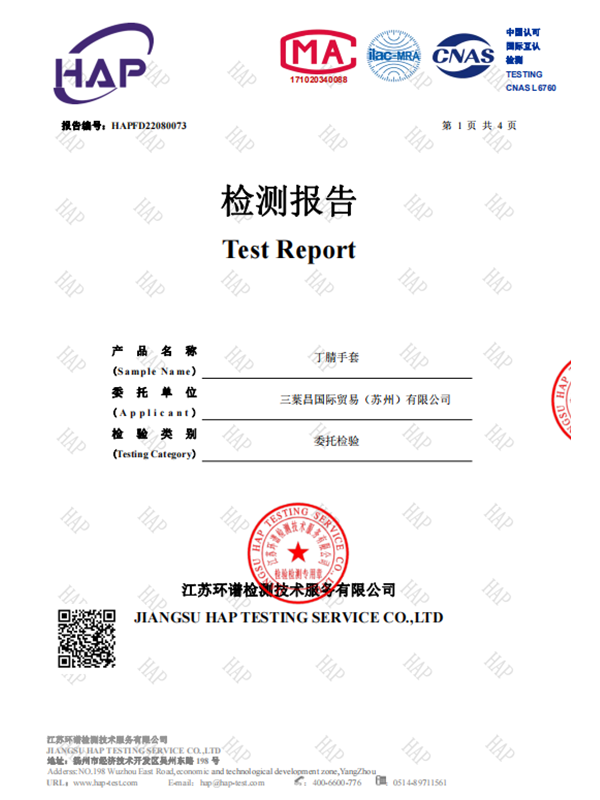

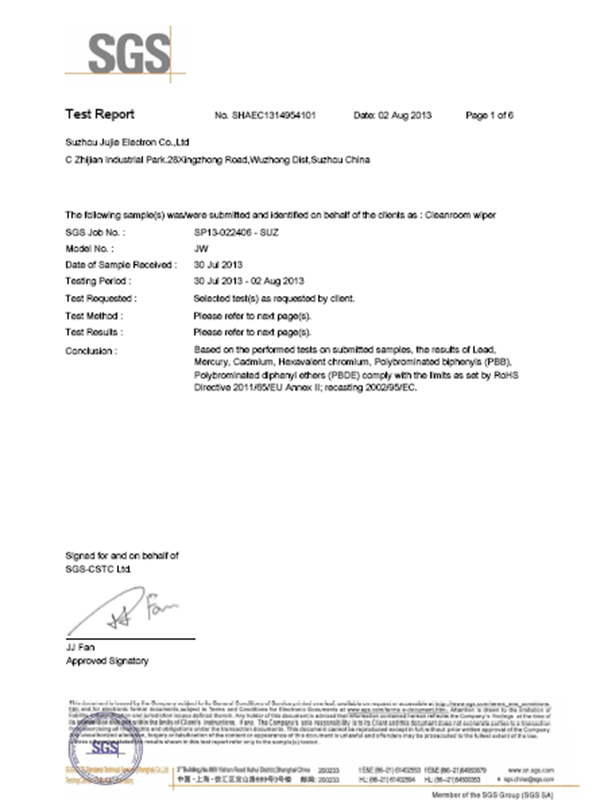

Suzhou Jujie Electronics Co., Ltd., a high-tech enterprise and a professional manufacturer of cleanroom shoe covers, ensures the consistent quality of every pair of shoe covers through a three-pronged approach: hardware upgrades, standard certification, and full-process testing. Its strengths lie in the following key areas:

1. Hardware Investment: Fully automated production lines and high-end equipment.

Production Capacity and Production Line Advantages: Following a wholly-owned investment expansion in 2018, the company boasts 48 automated weaving, washing, and shaping production lines, increasing production capacity tenfold and ensuring a stable supply of large-scale orders.

Clean Production Environment: Within the 33,000 square meter factory, 8,000 square meters of lint-free workshops are located. The cleanroom is built to ISO Class 5 and 6 standards and is NEBB-certified, eliminating contamination risks during the production process. High-end Production Equipment: Equipped with laser cutting and ultrasonic cutting machines imported from Japan, we achieve precise cutting and sealing of shoe covers, eliminating burrs and leaks. Testing equipment, such as infrared spectrometers and liquid particle counters, imported from Germany, the United States, and South Korea, ensures that each batch of products meets quality standards for quality and cleanliness.

2. Standard Certification: Dual compliance with international standards and industry requirements

Cleanroom Standards: Our antistatic and disposable shoe covers comply with ISO 14644, cleanroom and related controlled environments, and IEC 61340, meeting the stringent requirements of the electronics and pharmaceutical industries.

Company Qualifications: As a high-tech enterprise, we hold numerous patents and independent intellectual property rights. We adhere to the ISO 9001 quality management system throughout our entire R&D and production processes, ensuring systematic quality control.

3. Full-Process Inspection: "Zero-defect" control from raw materials to finished product

Raw Material Inspection: We conduct component analysis and cleanliness inspections on raw materials, such as plastics and fibers, to prevent unqualified materials from entering the production line. Production Process Inspection: Each production line is equipped with an online inspection system to monitor key shoe cover parameters such as size, sealing, and static resistance, ensuring timely removal of defective products.

Product Inspection: Samples from each batch undergo destructive testing, such as abrasion resistance and antistatic attenuation, as well as non-destructive testing, such as cleanliness and dimensional accuracy, to ensure 100% product quality.

Shoe Cover Types Produced by Suzhou Jujie Electronics Co., Ltd.: A Complete Product Matrix Covering Diverse Needs

Leveraging over 15 years of experience in cleanroom product development, Suzhou Jujie has developed three product categories: antistatic shoe covers, disposable shoe covers, and reusable shoe covers, catering to diverse industries and scenarios. These categories address diverse customer needs, from static control to basic protection.

1. antistatic Shoe Covers: The "Static Guardian" for High-Precision Cleanrooms

Product Features: Made from a composite of conductive fiber and wear-resistant fabric, they offer excellent static conductivity, are abrasion-resistant, tear-resistant, and reusable over 50 times. Applicable Applications: Suitable for ISO Class 5/6 cleanrooms such as electronic chip manufacturing, semiconductor packaging, optoelectronic displays, and aseptic pharmaceutical production, effectively preventing static electricity from damaging products.

Advantages: Suzhou Jujie's antistatic shoe covers are NEBB-certified, meeting the stringent static control requirements of cleanrooms and becoming the standard choice for customers in the electronics industry.

2. Disposable Shoe Covers: Convenient Protectors for a Wide Range of Applications

Product Features: Made of PE plastic or non-woven fabric, they are lightweight, easy to put on and take off, and are waterproof, dustproof, and anti-bacterial, with an extremely low per-use cost.

Applicable Applications: Suitable for hospitals, laboratories, food factories, and homes, meeting short-term, high-frequency, and low-cost protection needs.

Advantages: Suzhou Jujie's disposable shoe covers utilize ultrasonic cutting technology, resulting in smooth, burr-free edges that resist tearing during donning and doffing, enhancing the user experience.

3. Reusable Shoe Covers: An Economical Choice for Long-Term Operations

Product Features: Made of washable and abrasion-resistant polyester or nylon, they can be washed over 100 times, balancing protection and affordability. Suitable for use in environments where laboratory R&D personnel and factory workers, who frequently don and remove shoe covers, can reduce long-term costs.

Advantages: Suzhou Jujie's reusable shoe covers undergo special treatment to prevent pilling and deformation, maintaining long-term protective performance. They are the preferred choice for customers who prioritize cost-effectiveness.